- ZP

- China Foshan

- 60Days

- 10Sets/Months

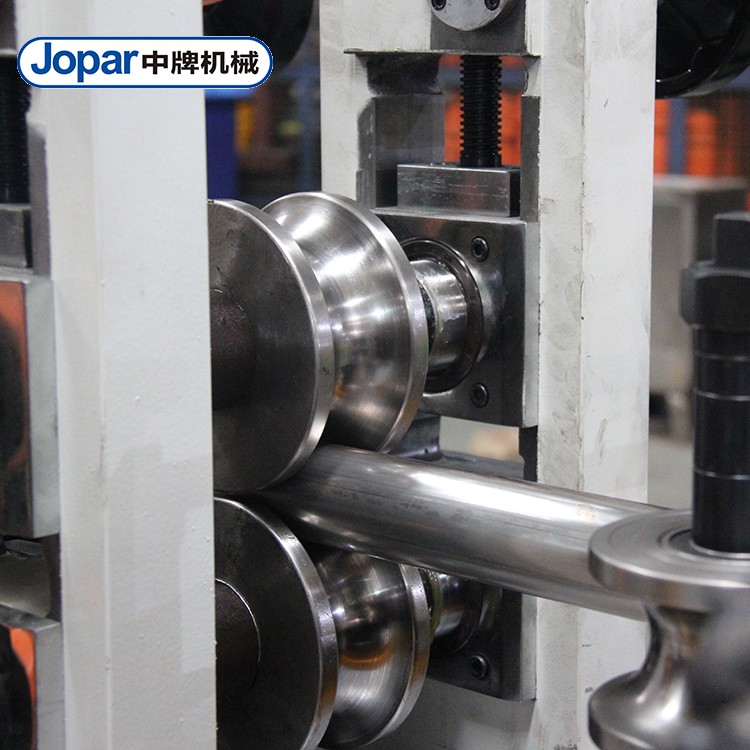

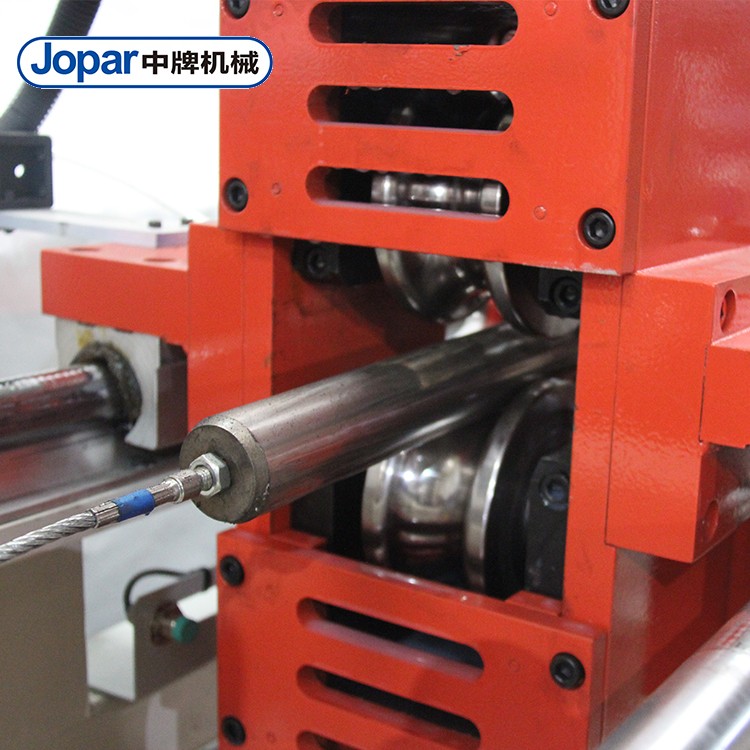

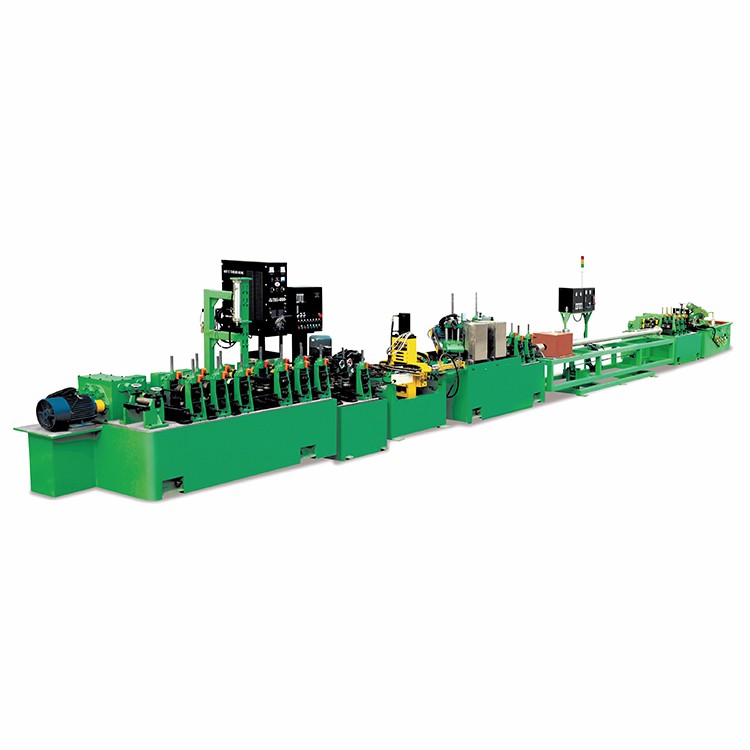

Industrial tube mill,Industrial pipe making machine is manufacturing stainless steel industrial pipes widely applied in Mechanical structure , Construction , Medical use , Refrigeration , Foods and Beverage handling equipment, Heating elements and Nuclear industrial etc. These pipe fittings usually have to bear a certain pressure inside the pipe, so the pipe must eliminate internal stress and remove the weld, to prevent cracks inside the pipe. The pipe fittings that need to withstand pressure will use annealing and eddy current detection equipment. Because of the high requirements for steel pipes in the industrial field, the steel pipes produced also require high quality. The annealing machine can remove the stress of steel pipe and to ensure that the production of steel pipe will not crack. The eddy current detection's role is to detect whether there are cracks in the material, whether the weld is unstable, and so on.

Industrial Exhaust Pipe Tube Making Machine

PRODUCT PROCESSES

Single or double side uncoiler-leveling section-welding stage-in-line inside weld bead remove section-outside welding bead grind section-first sizing section-in-line annealing section-final sizing section and straightening section-nondestructive testing-marking stage-fixed length-cut off-cut off-end-product upload stage.

TECHNICAL PARAMETERS

| Model |

Horizontal Shaft Size |

Vertical Shaft Size |

Out Diameter Range |

Thickness |

Drive Motor |

Dimension |

| ZP-I40 | 40mm | 25mm | 8-51mm | 0.5-2.0mm |

Front:7.5kw Rear:7.5kw |

29m*1.5m |

| ZP-I50 | 50mm | 30mm | 25-63mm | 0.5-3.0mm |

Front:7.5kw Rear:7.5kw |

31m*1.5m |

| ZP-I60 | 60mm | 40mm | 89-168mm | 0.6-3.5mm |

Front:7.5kw Rear:7.5kw |

34m*1.8m |

| ZP-I80 | 80mm | 50mm | 89-168mm | 1.0-4.5mm |

Front:7.5kw Rear:7.5kw |

40m*2.5m |

| ZP-I100 | 100mm | 60mm | 114-219mm | 1.0-5.0mm |

Front:7.5kw Rear:7.5kw |

44m*3.0m |

|

OFFERING THE PROFSSIONAL WELDED TUBE SOLUTIONS |

||||||

PRODUCT PROCESSES

Single or double side uncoiler-leveing section-forming section-welding stage-in

-line inside weld bead remove section-outside welding bead grind section-first

sizing section-in line annealing section-final sizing section and straightening section-nondestructive testing-making strage-fixed-fixed length-cut off-end-

produc upload stage.